Custom Disc Brushes

Custom disc brushes are circular brushes characterized by tufts arranged perpendicular to the base. These brushes consist of a central core and radially arranged bristles, forming a circular shape that facilitates optimal contact with surfaces. Brushcustom’s custom disc brushes are crafted from high-quality materials, ensuring durability and precision in performance.

Various Types of Industrial Disc Brushes Available

There are various types of industrial disc brushes available, each designed for specific applications. Customizable aspects include brush dimension, base materials, core materials, bristle materials, brush patterns, etc., in order to better cater to customer preferences.

1. Disc Brush Dimensional Range

Tailor your cleaning, polishing, and deburring processes with a diverse range of dimensions, ensuring precision through customizable sizes.

Diameter: Disc brushes typically come in diameters ranging from a few inches to several feet. Smaller disc brushes may have diameters as small as 10mm, while larger ones can exceed 48 inches (1200mm) or more.

Brush Thickness: The thickness of disc brushes can vary based on the intended application and desired aggressiveness. Common thickness ranges from 4mm to 200mm or more.

2. Disc Brush Base

The base of a disc brush refers to the core or backing material that holds the bristles in place. It plays a crucial role in providing stability and support to the bristles, allowing them to effectively perform the desired brushing action.

Plastic Base

Disc brushes with a plastic base are lightweight and cost-effective. Plastic bases provide flexibility and can be molded into various shapes to suit specific applications. They are commonly used in light-duty brushing tasks.

Metal Base

Disc brushes with a metal base offer durability and strength. Metal bases provide rigidity and stability, making them suitable for heavy-duty applications that require more aggressive brushing or cutting action. Stainless steel, steel, and aluminum are commonly used metals for disc brush bases.

Composite Base

Composite bases combine the advantages of both plastic and metal. They are composed of a mixture of materials, such as fiberglass, carbon fiber, or reinforced plastics. Composite bases offer a balance of strength and lightweight properties, making them suitable for a wide range of applications.

Wood Base

In some cases, disc brushes may have a wooden base. Wood bases provide a natural aesthetic and are typically used in specialized applications where a softer or gentler brushing action is required.

3. Disc Brush Patterns

When it comes to disc brush patterns, different bristle arrangements can impact the brushing performance and efficiency of the brush.

Radial Pattern

The bristles are arranged in a spoke-like configuration radiating from the center of the brush towards the outer edge.

Spiral Pattern

The bristles are arranged in a continuous spiral shape starting from the center and winding towards the outer edge of the brush.

Concentric Rings Pattern

The bristles are arranged in circular rings around the center of the brush. Each ring has a different diameter, creating multiple rows of bristles.

Staggered Pattern

The bristles are arranged in a staggered formation across the disc brush base.

4. Core Material Options

Disc brush cores, also known as brush hubs or brush centers, provide structural support and stability to the brush assembly.

Synthetic:

Include materials such as acetal, nylon, PVC, and UHMW for versatile applications.

Wooden

Provide a natural and traditional option for certain industrial contexts.

Aluminium:

Offer a lightweight yet durable choice suitable for specific applications.

Steel or Stainless Steel:

Ensure robustness and resilience, with stainless steel providing corrosion resistance.

5. Bristle Material Options

Disc brush bristle materials are selected based on the specific application requirements, desired performance, and compatibility with the surface being brushed.

Nylon:

Nylon bristles are versatile and widely used in various applications. They offer excellent abrasion resistance, flexibility, and durability. Nylon bristles work well on both delicate surfaces and tougher cleaning or deburring tasks.

Polypropylene:

Polypropylene bristles are known for their chemical resistance and flexibility. They are often used in applications where resistance to solvents, acids, or other chemicals is required. Polypropylene bristles can effectively clean or sweep surfaces without causing damage.

Stainless Steel:

Stainless steel bristles are suitable for heavy-duty applications that require aggressive brushing or removal of tough debris. They offer high strength, durability, and resistance to corrosion. Stainless steel bristles are commonly used in metalworking, weld cleaning, or rust removal tasks.

Brass:

Brass bristles have softer properties compared to stainless steel, making them ideal for lighter cleaning applications. They provide good durability and corrosion resistance. Brass bristles are commonly used in polishing, surface preparation, or decorative finishing tasks.

Natural Fibers:

Natural fiber bristles, such as horsehair or tampico, are often used in delicate cleaning or finishing applications. They offer gentle yet effective brushing action and are commonly used in industries like woodworking, glass, or electronics.

Abrasive Bristles:

Disc brushes can also be equipped with abrasive bristles for applications requiring aggressive material removal or surface blending. These bristles are typically made of materials like silicon carbide, aluminum oxide, or diamond grit, depending on the desired level of abrasiveness.

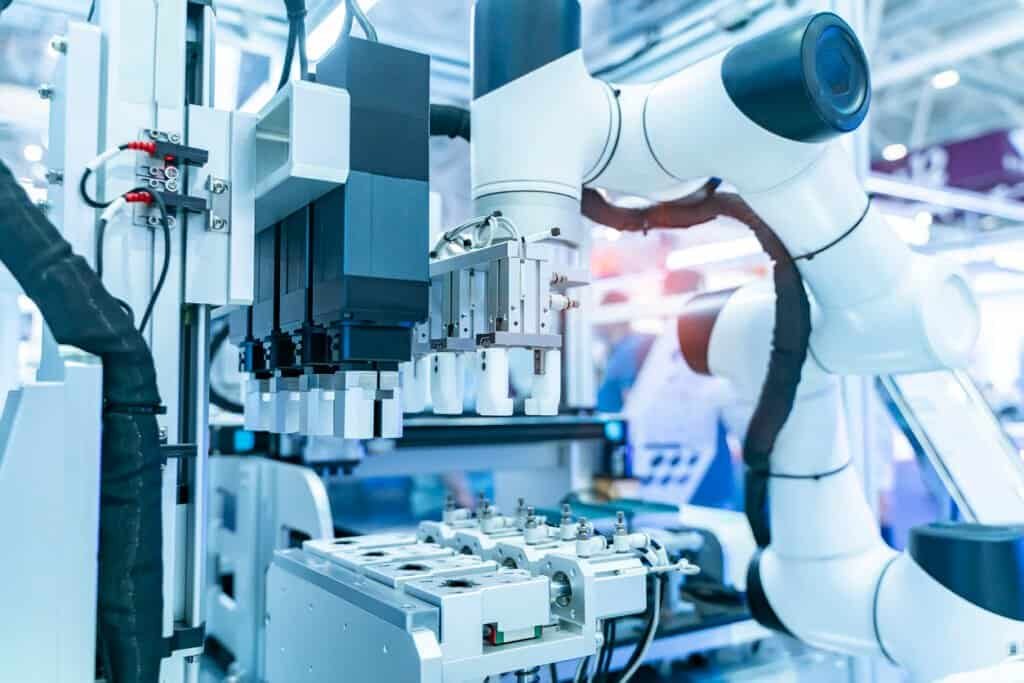

Our Top-Tier Disc Brushes to Suit Different Applications

Different tasks need different block brushes. Good news! Our custom disc brushes of high quality are engineered to deliver exceptional performance and versatility, suitable for a wide array of applications.

PCB Manufacturing

Disc brushes play a crucial role in the manufacturing and cleaning of printed circuit boards (PCBs) in the electronics industry, such as solder paste cleaning, post-etching cleaning, hole cleaning, edge rounding and chamfering, etc.

Woodworking & Furniture Finishing:

Disc brushes are widely used in woodworking and furniture finishing processes to achieve desired surface textures, smoothness, and finishes. They can effectively remove imperfections, rough spots, and sharp edges, preparing the wood for further finishing.

Automotive Industry

Disc brushes find various applications in the automotive industry, contributing to processes such as cleaning, deburring, surface preparation, and polishing.

Medical Equipment Preparation

Disc brushes assist in the preparation and cleaning of medical equipment in various healthcare settings, such as sterilization cleaning, endoscope cleaning, surgical instrument cleaning, etc.

Food Processing Industry

Disc brushes find applications in the food processing industry for cleaning and sanitizing conveyor belts, equipment, and surfaces. They assist in removing debris, residue, and contaminants, ensuring hygiene and food safety.

Glass & Ceramic Processing

Disc brushes are utilized for edge & glass frosted finishing, surface cleaning, deburring and chamfering, ceramic glazing preparation and engraving & marking of glass and ceramic products.

Why Choose Us?

At Brushcustom, you can expect superior quality, customization options, durability, innovation, and excellent customer service. We aim to be your trusted partner in providing reliable and efficient disc brushes for your specific applications.

100% customizable

We offer a range of customization options for disc brushes, even for small orders. You can specify your desired bristle material, diameter, density, stiffness, and overall design. This allows us to tailor the brush to meet your specific needs and optimize its performance for your application.

Versatility

Our disc brushes are designed to handle a wide range of applications and materials. Whether it’s cleaning, deburring, polishing, or surface preparation, our brushes offer versatility in different industries and can adapt to various materials and surface conditions.

Quality Control

We have stringent quality control measures in place to ensure that our disc brushes meet the highest standards. Every brush goes through rigorous testing and inspection to verify its strength, performance, and reliability before it reaches our customers.

Quick Turnaround Time

We understand the importance of timely delivery, even for small orders. Our efficient production processes enable us to provide a quick turnaround time for customized disc brushes. We prioritize your order and work diligently to ensure that your customized brushes are delivered within the agreed-upon timeframe.

Competitive Pricing

We offer competitive pricing for our disc brushes without compromising on quality. We understand the importance of cost-effectiveness in business operations, and we strive to provide value for your investment.

FAQs

What are wire disc brushes?

Wire disc brushes are a type of industrial brush consisting of a circular disk-shaped base with wire bristles attached radially around its outer edge. These brushes are commonly used for various surface preparation, cleaning, deburring, and finishing applications in industries such as manufacturing, metalworking, automotive, aerospace, and more.

How does a grinder brush disc differ from standard wire disc brushes?

A grinder brush disc typically has a cup-shaped design, resembling a wheel or a saucer, whereas a standard wire disc brush is flat and circular. Grinder brush discs excel in aggressive material removal and are ideal for heavy-duty applications, while standard wire disc brushes offer versatility and can be used for a wider range of cleaning, deburring, and finishing tasks.

How do disc brushes work?

Disc brushes work by utilizing the rotation of a circular disc-shaped brush to accomplish various tasks. The bristles or filaments on the disc brush come into contact with the surface being treated, allowing for effective cleaning, polishing, or deburring.

Are disc brushes suitable for both wet and dry applications?

Yes. For dry applications, disc brushes with bristles made from materials like nylon, wire, or abrasive grains are commonly used. For wet applications, disc brushes with synthetic or natural fibers that can withstand exposure to water or other liquids are often utilized. These brushes are typically more resistant to moisture and can be used in conjunction with water, cleaning agents, or coolant fluids to enhance their performance.

Can brush-disc configurations be customized?

Yes. Disc brushes can often be customized or made to specific specifications to meet the unique requirements of different applications. Brushcustom, a reliable industrial brush manufacturer, can offer great customization options and high-quality products.

Contact Us for Your Industrial Disc Brush Needs!

- All information and uploads are secure and confidential.